MIS-FlexTM

MIS-FlexTM (Minimally-Invasive-Surgery Flex)

With recent investments of increased capability and capacity, MFS has developed MIS-FlexTM (Minimally-Invasive-Surgery Flex) which can accommodate low to high volume on the most demanding medical imaging flexible circuits.

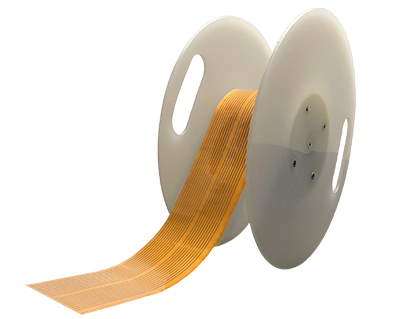

MIS-FlexTM enables a long flex of 2 meters in length with a typical Line/Space requirement of 35um/35um and part width of 1mm.

MIS-Flex™ enables a long flex of 2 meters in length with a typical Line/Space requirement of 35um/35um and part width of 1mm

This requirement is intended for Minimally Invasive Surgeries where micro copper conductors (FPC in this case) are inserted into the human body through a catheter to transmit image and video data in real time.

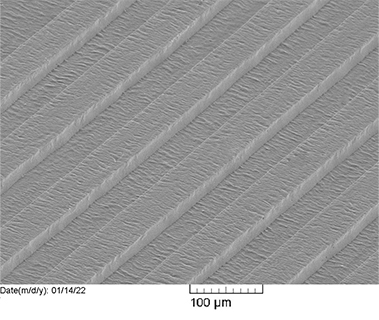

Through (1) tightly controlled photolithographic processes, (2) advanced software design algorithms, and (3) stable dielectrics, MIS-Flex™ minimize the number of layers, enhance reliability, increase routing density and reduce form factor to allow for minimum part width. In addition, through advanced software simulation, MIS-Flex™ models and provides for the required impedance requirement of the intended signal frequency. This is especially important for high-speed data transmission where signal integrity is highly susceptible to noise.

- Flexible printed circuit for catheter cables

- 2 meters in length

- Minimum Part width: 1.0mm ± 50um accuracy

- Copper Trace/Space: 35um/35um

- Single-side, Bare-back

- Impedance modeling & control

Our experienced application engineers who are knowledgeable in medical imaging flex can help evaluate your designs if you have an existing product at volume or an idea or concept for a future probe. MFS design center and manufacturing production teams can meet you where you are in your product life cycle and illustrate how our precision lithography and diversified dielectric material choices can make your product superior.

Contact us to set up a design consultation today. Email : contactmfs@mfstechnology.com